Smooth high-density polyethylene geomembrane

The smooth high-density polyethylene geomembrane is made from polyethylene resin as the base material, with a small amount of antioxidants, light stabilizers, and other additives produced through blow molding or extrusion methods. It uses polyvinyl chloride resin combined with plasticizers, ultraviolet inhibitors, anti-aging agents, and stabilizers.

Product Features:

Excellent resistance to environmental stress cracking, outstanding impermeability, high barrier performance, excellent elongation and wear resistance. The product has high tensile strength, low-temperature resistance, high-temperature resistance, aging resistance, high tear strength, and good adhesion properties. It employs single-sided or double-sided roughening technology, significantly enhancing engineering adaptability.

Rough surface high-density polyethylene geomembrane

Rough surface high-density polyethylene geomembrane is a new type of impermeable material. The single rough surface and double rough surface geomembranes increase the friction coefficient and anti-slip function, making them more suitable for steep slopes and vertical impermeability, thus enhancing project stability.

Product Features

Rough surface high-density polyethylene geomembrane has excellent temperature adaptability, weldability, weather resistance, and good aging resistance, chemical corrosion resistance, environmental stress cracking resistance, and puncture resistance. Therefore, it is particularly suitable for underground projects, mining projects, landfills, and sewage or waste treatment sites as impermeable materials.

Low-Density Polyethylene Geomembrane

The thickness range of low-density polyethylene geomembrane i s 0.3~3.0mm;th e thicknes s range of environmentally friendly linear low-density polyethylene geomembrane is 0.5~3.0mm; the widt h range of polyethylen e geomem-brane i s 4~9m. Using a larger width can reduce Material splicing seams im-prove construction efficiency and construction quality, save material usage,and reduce project costs.

Features

Low-density polyethylene geomembrane has good ductility, smal l specific gravity, low temperature resistance, good thermal insulation effect, excellent waterproof performance, and easy welding.

Geotechnical composite membrane

Geotechnical composite membrane is an impermeablematerial made from geotextile as the substrate, polyeth-ylene geomembrane, polyethylene geomembrane as themembrane material, and processed by casting, rolling, andremote external heating composite processes.

Product Features

Composite geomembranes have functions of drainage, fil-tration,and protectior.

Long filament spunbond needle-punched non-woven geotextile

Long filament spunbond needle punched nonwoven geotextile is a thin sheet, fiber mesh orfloc like geotextile formed by friction and/or adhesion of oriented or randomly orientedfibers, also known as non-woven geotextile.

Product Features:

The geotextile has high tensile strength, as it uses plastic flat yarn, maintaining sufficient strength and elongation in both dry and wet conditions. It is corrosion-resistant, capable of withstanding corrosion for a long time in soils and waters with different acidity and alkalinity. It has good permeability due to the gaps between the flat yarns, thus providing excellent drainage performance.

Membrane splitting machine woven geotextile

Fractured film fiber woven geotextiles are divided into polypro-pylene, polyethylene and other materials according to their rawmaterials; According to the structure of the yarn used, it can bedivided into geotextiles made of cut film fibers (yarn), split filmfibers (yarn), and other split film fibers.

Product Features:

It has functions such as isolation, filtration, drainage, protection, stabilization, and reinforcement. It can adapt to uneven foundations, resist damage from external construction forces, reduce creep, and maintain its original functions under long-term loads.

Polyester filament burnt geotextile

Features: High strength, high density, corrosion-resistant, waterproof, tear-resistant, puncture-resistant, and impact-resistant, with a width of 5.1 meters.

Uses: In water conservancy, for reinforcement of rivers, lakes, seas, and dams, reservoir reinforcement, seepage prevention, and emergency rescue; in transportation, for soft foundation reinforcement of highways, railways, and airports, slope protection, and green isolation belts; in port and lock engineering; in power, for thermal power ash dams, nuclear power plant foundation treatment, and hydropower dam construction; and other applications such as tunnels, subway projects, environmental protection projects, and navigation channel management.

PP/PET filament woven geotextile

Woven geotextile is a material made from high-strength synthetic fiber yarns, typically using polyester or polypropylene fibers as raw materials. It has a mesh structure that can effectively resist soil erosion and scouring, while also increasing the tensile strength and shear strength of the soil. It is specifically used for soil reinforcement and protection.

Product Features:

High strength, high density, corrosion-resistant, waterproof, tear-resistant, puncture-resistant, and roof rupture-resistant.

Short fiber needle-punched non-woven geotextile

Short fiber needle-punched non-woven geotextile: made from synthetic fibers, formed by dry method netting and reinforced by needle punching. It enhances the tensile strength and deformation resistance of the soil, improving the stability of the construction structure and the quality of the soil; effectively diffuses concentrated stress, transmits or decomposes it, preventing damage to the soil from external forces; prevents mixing between upper and lower layers of sand, soil, and concrete; the mesh structure formed by the irregular fiber organization has strain and mobility, making it difficult for the pores to become blocked.

Product Features:

High strength, high density, corrosion-resistant, waterproof, tear-resistant, puncture-resistant, and top-breaking resistant.

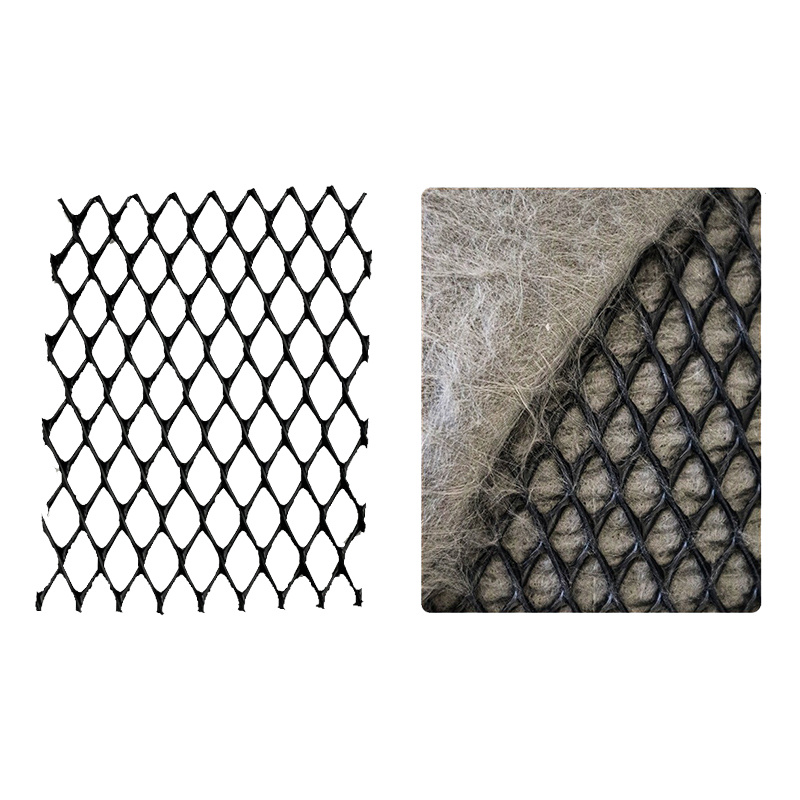

Double-ribbed geocomposite drainage net

A drainage network refers to a three-dimensional structure composed of plastic mesh withdouble-sided adhesive permeable geotextile, which can replace traditional sand and gravellayers. The three-dimensional geotextile core includes a thick vertical rib, as well as a diago-nal rib at the top and bottom. lt can quickly discharge groundwater from roads and has apore maintenance system that can block capillary water under high loads. At the same time,it can also serve as an isolation and foundation reinforcement function. A new type of geo-synthetic material.

Product Features

Geotechnical drainage networks have high vertical drainage capacity. The staggered rein-forcement bars can effectively prevent the geotextile from being embedded in the drainagechannel, allowing the geotextile drainage network to maintain high drainage performanceunder high loads. The width of the geosynthetic drainage network reaches 4 meters, reducingoverlap and increasing construction efficiency. The overlap loss has been reduced by morethan 2%, indirectly saving costs.

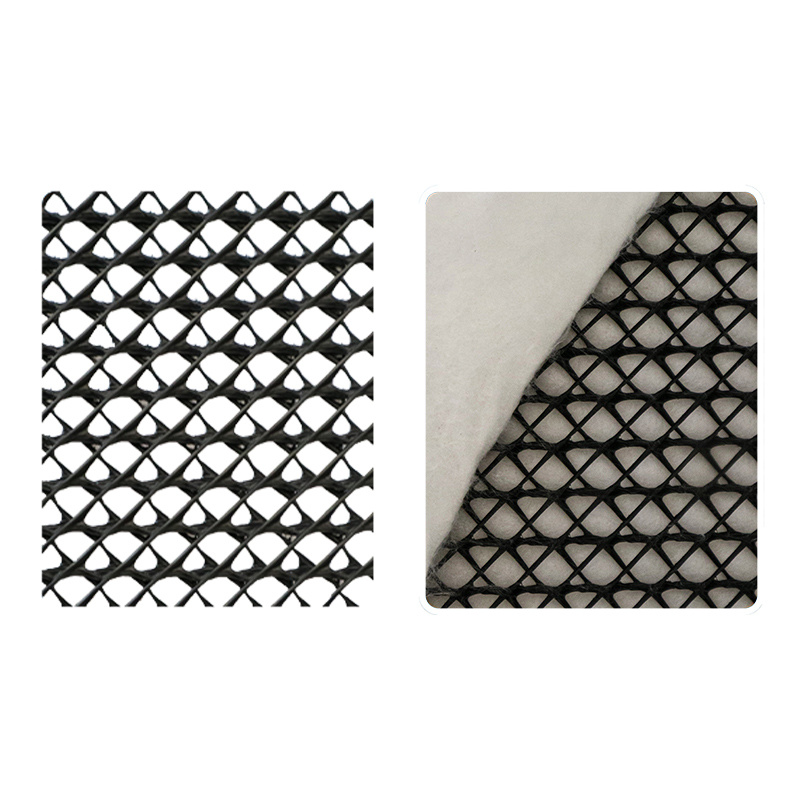

Three-dimensional geocomposite drainage network

A drainage network refers to a three-dimensional structure composed of plastic mesh withdouble-sided adhesive permeable geotextile, which can replace traditional sand and gravellayers. The three-dimensional geotextile core includes a thick vertical rib, as well as a diago.nal rib at the top and bottom. lt can quickly discharge groundwater from roads and has apore maintenance system that can block capillary water under high loads. At the same time.it can also serve as an isolation and foundation reinforcement function. A new type of geo-synthetic material.

Product Features

Geotechnical drainage networks have high vertical drainage capacity. The staggered rein-forcement bars can effectively prevent the geotextile from being embedded in the drainagechannel, allowing the geotextile drainage network to maintain high drainage performanceunder high loads. The width of the geosynthetic drainage network reaches 4 meters, reducingoverlap and increasing construction efficiency. The overlap loss has been reduced by morethan 2%, indirectly saving costs.

The roll is a polymer roll made of polyester fiber fabric as reinforcement,which is combined into one by a special extrusion coating process to make thedouble-sided PVC plastic layer and the polyester reinforcement in the middle.The combination of the advanced polyvinyl chloride plastic layer with the retic-ulated polyester fabric gives the coil excellent dimensional stability and lowcoefficient of thermal expansion. lmprove the long-term performance of coilexposed directly to the natural environment. Construction method: Hot airwelding to ensure the weld effect.

Product Features:

PVC waterproof coil has high tensile strength, good elongation, small thermalsize change rate, good weldability, joint hot air welding and the base materialinto one, with good water vapor diffusion, condensate easy release, The moisture and moisture left at the base are easy to discharge, resis-tant to aging, ultraviolet radiation, chemical corrosion and root penetration. lthas good flexibility at low temperature (-20℃), long service life (25 years onthe roof, more than 50 years underground), and no environmental pollution.The surface of the color reflects the ultraviolet irradiation, and the surface ofthe PVC waterproof coil absorbs less heat. Low temperature, excellent flexibil-ity and extensibility, high tensile strength, excellent dimensional stability, highmechanical strength, erosion resistance, root permeability resistance, weatherresistance and UV linearity resistance, hail resistance.