Construction Technology

1、The filter function

Application products:

Filament spunbonded needle-punched nonwoven geotextile, staple fiber needle-punched nonwoven geotextile, PP/PET filament woven geotextile, polyester filament singeing geotextile.

Application Engineering:

Municipal and infrastructure construction projects for water conservancy, dikes, highways, railway subgrades, landfills, airports, bridges, seas, ports, tunnels, etc.

Applications:

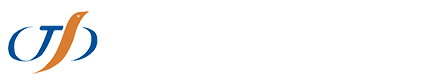

★Retaining wall and drain filter

The slope protection of the roadbed, the retaining wall, the back of the retaining wall, and the drainage ditch can be made by using a filament spunbonded geotextile as a filter layer.

★Drainage of dams and slope protection

The back side of the upstream and downstream faces of earth-rock dam core walls or inclined walls, earth-rock cofferdams, slope protection and other water-blocking structures. A filament-spun needle-punched geotextile can be used as a filter layer.

2、Drainage function

Application products:

Filament spunbonded needled nonwoven geotextile.

Application Engineering:

Municipal and infrastructure construction projects for water conservancy, dikes, highways, railway subgrades, landfills, airports, bridges, seas, ports, tunnels, etc.

Applications:

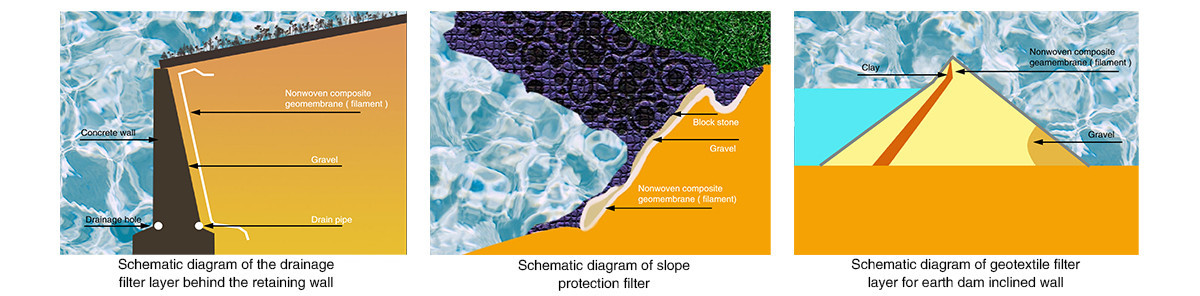

★Subgrade, pavement drainage

The combination of engineering measures for the roadbed and road surface with spunbonded knit geotextiles can eliminate surface water and lower the groundwater level to maintain the stability of the roadbed.

3、Isolation function

Application products:

Filament spunbond needle-punched nonwoven geotextile, staple fiber needle-punched nonwoven geotextile, PP/PET filament woven geotextile, polyester filament singeing geotextile

Application Engineering:

Municipal and infrastructure construction projects for water conservancy, dikes, highways, railway subgrades, landfills, airports, bridges, seas, ports, tunnels, etc.

Applications:

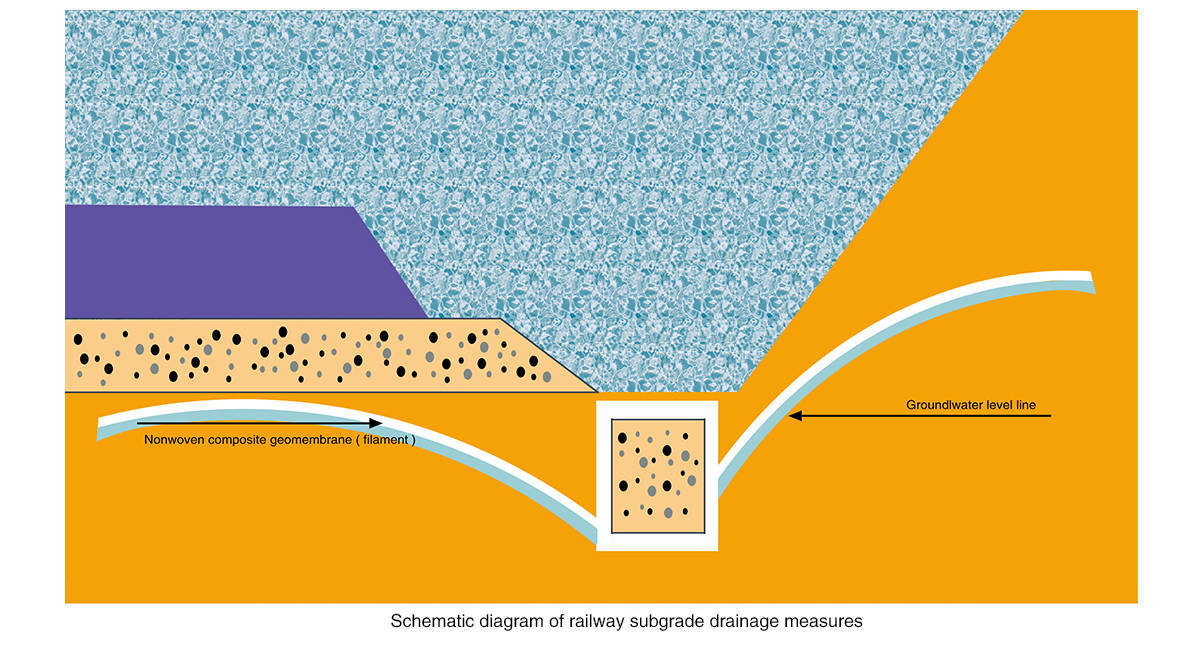

★Beach dikes, harbor piers and anti-wave lifting projects, can be laid on the software soil layer with long-spun spunbonded geotextiles, and then filled with stone to improve the strength of the foundation.

★Landfill isolation and anti-seepage landfills can be insulated and impervious by composites of filament spunbonded geotextiles and geomembranes to prevent toxic liquids from entering the ground.

And the spread of harmful gases, reduce environmental pollution and improve land use efficiency.

4、Reinforcement function

Application products:

Filament spunbonded needle woven non-woven geotextile, staple fiber needled nonwoven geotextile, PP, PET filament woven geotextile, polyester filament singeing geotextile

Application Engineering:

Municipal and infrastructure construction projects for water conservancy, dikes, highways, railway subgrades, landfills, airports, bridges, seas, ports, tunnels, etc.

Applications:

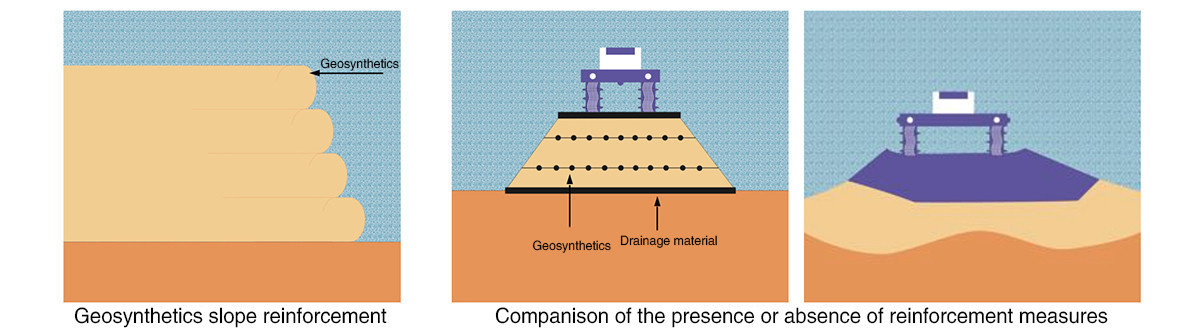

★Soil slope reinforcement

The slopes of highways, railways, etc., which are reinforced by filament spunbonded needle-punched geotextiles, can improve the stability of slopes and increase the slope to reduce land use.

★Roadbed reinforcement

In the roadbed filling, the reinforcement of the subgrade can be improved by the use of filament spunbonded geotextile reinforcement.

5、Anti-seepage function

Application products:

Nonwoven composite geomembrane (filament)

Application Engineering:

Anti-seepage of railway subgrade, reservoir dam, landfill, tunnel embankment and other projects.

Applications:

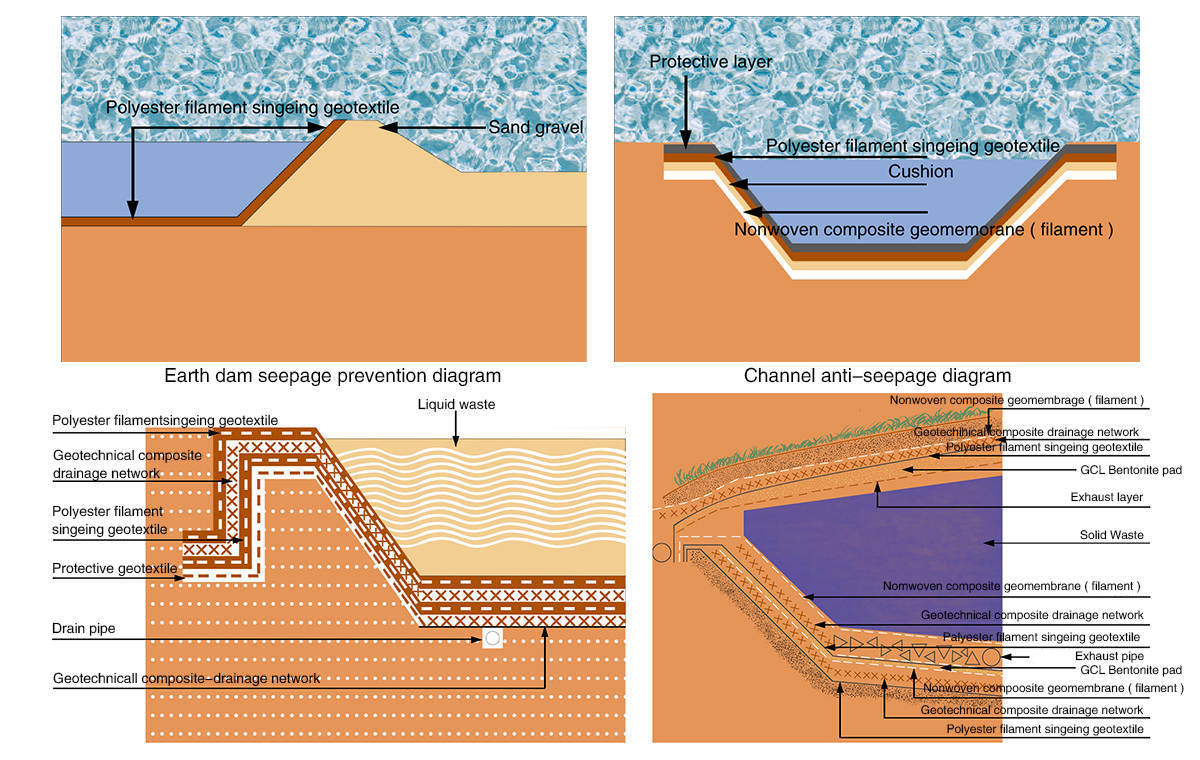

★Dam seepage prevention

Dam sloping wall, core wall, horizontal seepage of dam on permeable foundation and prevention of vertical cutoff wall, concrete dam and roller compacted concrete dam

For the seepage layer, etc., a composite material of a filament spunbonded geotextile and a geomembrane may be used as an anti-seepage.

★Canal anti-seepage

For the irrigation and water diversion channels, the composite material of filament spunbonded needle geotextile and geomembrane is used as the anti-seepage layer, which is convenient for construction.

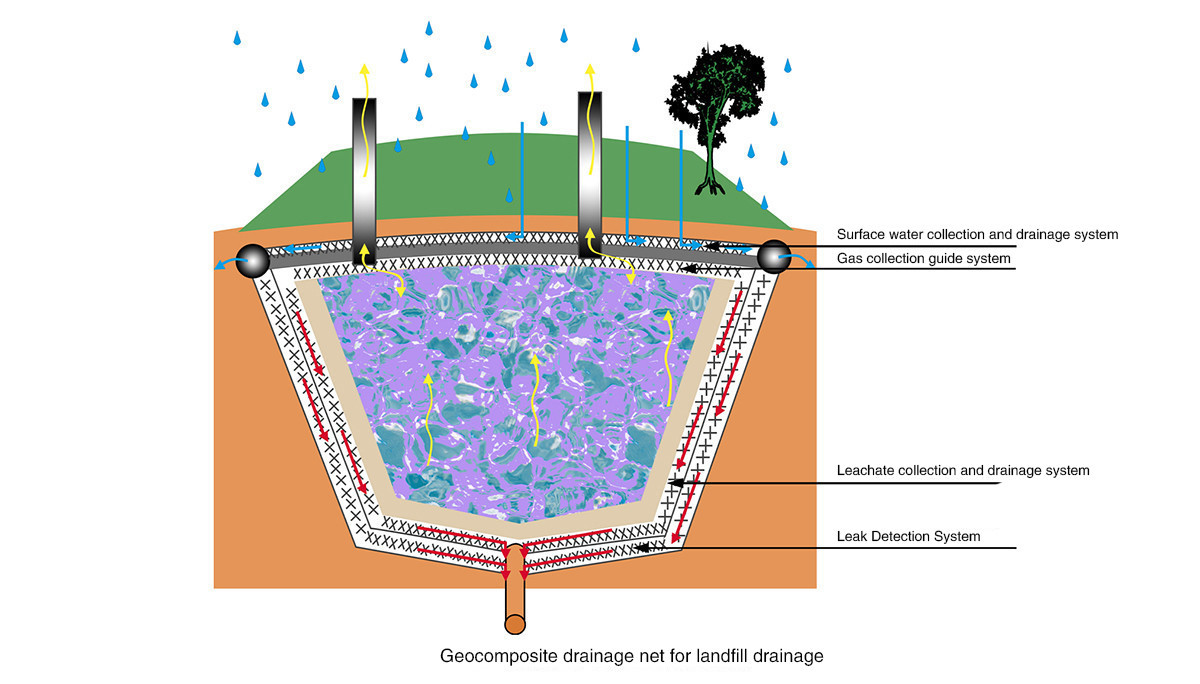

Advantages of using geocomposite drainage network in landfill

The geocomposite drainage net is made of double-sided composite polyester or polypropylene non-woven geotextile. The drainage net core is made of new high-density polyethylene raw materials, adding 2-3% carbon black and anti-ultraviolet and anti-oxidative stabilizers , processed by a special extrusion method. All quality control indicators are strictly tested before the materials leave the factory.

Geocomposite drainage network has deep drainage channels, which are used to replace traditional drainage materials such as sand and gravel. The material has good creep properties and long-term resistance to biochemical corrosion and fouling, and can be used in harsh environments. The series of double-ribbed geotechnical drainage mesh cores are available in four conventional sizes: 5mm, 6.3mm, 7mm, and 8mm, and the maximum thickness can reach 9.5mm. The thickness of the series of three-dimensional geotechnical drainage mesh is 6.3mm, 7mm, 8mm, 9mm.

The width of the double-rib composite drainage net reaches 4.4 meters, and the width of the three-dimensional composite drainage net reaches 4 meters, which reduces the lap loss and increases the speed of auxiliary construction. Geocomposite drainage net is a conventional composite 200g/m² filament geotextile with an equivalent pore diameter of more than 0.2mm and good water permeability. Other specifications of geotextiles can also be selected, such as short-filament geotextiles or special-purpose spun geotextiles.

Sealed ground surface water drainage system

The function of the enclosure surface water drainage system is to discharge the precipitation that penetrates into the enclosure anti-seepage liner, so as to prevent the water head of the liner from being too high, resulting in the destruction of the enclosure system.

Geocomposite drainage network has high plane drainage performance, which can quickly remove surface seepage and prevent sliding damage due to saturation of the covering soil.

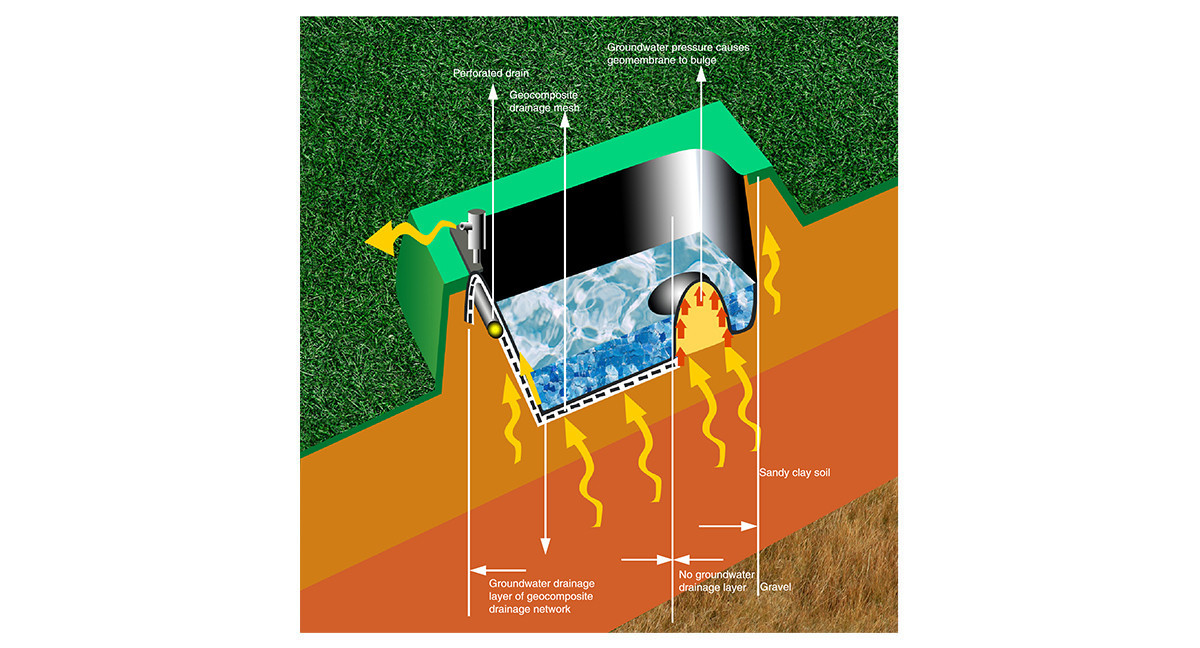

Groundwater Drainage System

The groundwater table in the landfill area of the landfill is high, and the groundwater pressure may destroy the impermeable liner. A groundwater drainage layer is required to discharge groundwater. The water pressure of the slope dam body of the landfill is too high, which may cause damage to the slope or the dam body and the anti-seepage layer of the slope.

The geocomposite drainage network is used as the groundwater drainage layer, which can drain the groundwater in a short time and prevent the impermeable liner from being damaged by excessive water pressure. Geocomposite drainage net has high tensile strength and can strengthen the foundation. Geocomposite drainage network is used for seepage diversion of slopes or dams, which can collect and discharge seepage from the slopes of mountains, eliminate the tendency pressure applied to the anti-seepage layer, and eliminate the damage caused by water pressure.

Leachate collection and drainage system

The leachate collection and discharge system is the horizontal drainage system of the landfill. Its function is to quickly discharge the leachate in the anti-seepage liner system, so that the water head of the liner system is less than 30cm required by the specification. Geocomposite drainage nets can replace natural drainage materials and increase the effective landfill space. Especially for slope leachate drainage, traditional drainage gravel cannot be landfilled, and the geocomposite drainage network can be constructed very conveniently and is basically not limited by the slope. Geocomposite drainage net has long-term hydraulic properties and creep resistance, which can ensure the long-term drainage performance of the system under harsh conditions. The width of more than 4 meters is easier to construct than the narrow drainage network, reducing overlapping and stronger integrity.

The geocomposite drainage net is used for the drainage of the site leachate, and a corresponding protective layer needs to be set up.

Leak Detection System

Hazardous waste landfills or more demanding domestic waste landfills require the use of a double liner system. A layer of geocomposite drainage network is laid between the two layers of anti-seepage geomembrane to form a leakage detection system, also known as a secondary leachate drainage system. The main function of the leakage detection system is to warn the leakage of the main anti-seepage liner, and at the same time collect and drain the leaked leachate.

The geocomposite drainage net has a high plane hydraulic conductivity, which can quickly discharge the leachate leaking from the upper anti-seepage liner, and discharge the leachate to the observation point in a very short time.

Closure gas guide and exhaust system

Landfill gas collection systems are used to collect gases such as methane and carbon dioxide that collect under the impermeable layer. The accumulation of landfill gas under the liner may cause the destabilization of the closure cover, resulting in sliding failure of the closure. The geocomposite drainage net replaces sand and gravel, collects the gas generated by the guide and discharge of garbage, and ensures the stability of the closure structure.

Water is one of the main causes of road failure. Good drainage can prolong the life of the road. To maintain sufficient supporting capacity of the road and prolong the service life of the road, there must be a good drainage system. The design life of an existing road with good drainage is 2 to 3 times longer than a road without drainage.

On contaminated ballast, irregular settlement of the rails may occur. The tamping method can restore the geometric shape of the rails in a short time, and the ballast after the repair will soon deteriorate, and the speed of the train has to be limited. A clean track bed can maintain the ideal geometry of the rail for a longer period of time than a soiled track bed; a soiled track bed does not have the required elasticity, and the impact of the wheels on the track joints may break the concrete sleepers. Sleepers can also rot due to insufficient ballast drainage. In the railway track bed of the plot, the rails can obtain the ideal geometrical position and are not limited by the speed.

Geocomposite drainage network can be used for roadbed drainage and pavement drainage, for railway subgrade drainage and subgrade drainage. Replacing the traditional gravel drainage layer, it has the superior performance that the gravel drainage layer does not have.